Steel Detailing and Connection Design Services – Steel Detailing Services – Connection Design Services – Steel Detailing and Connection Design Service Provider

Because of its integration with AutoCAD, you can use the Object ARX interface in AutoCAD to allow you to manipulate and edit objects using AutoCAD commands. It also enables you to work with very small to very complex sizes.

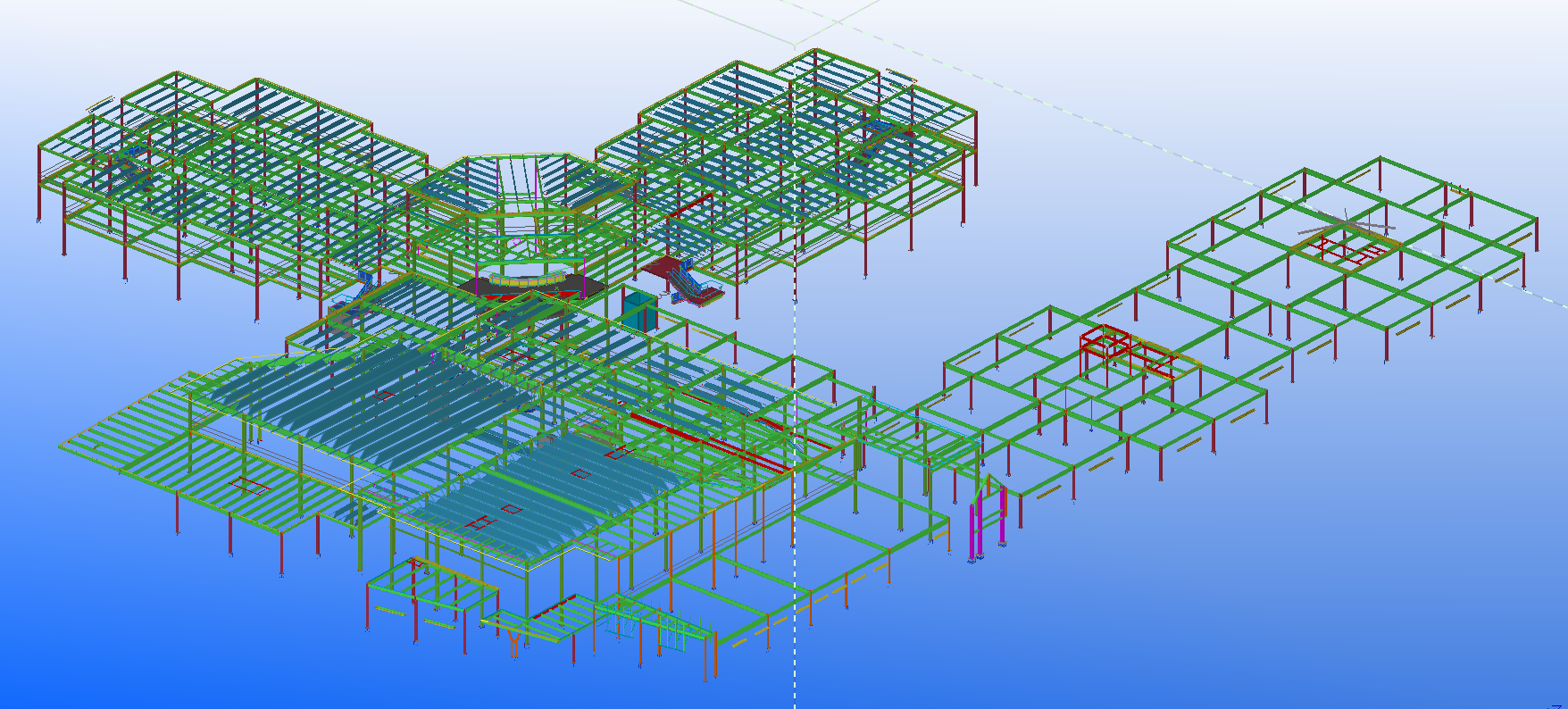

Global Detailing Consultant Group, we understand that accurate and detailed steel detailing is essential for any successful construction project. Our expertise in providing steel detailing services, as well as connection design services, is critical to ensuring that the final product meets the client’s specifications.

Our team’s ability to create detailed and accurate drawings that take into account the unique requirements of each project is essential to ensuring that the final product is of the highest quality. We appreciate your commitment to providing high-quality steel detailing and connection design services, and we believe that your experience and expertise will be an asset to any project.

We understand that connection design is a critical aspect of steel construction, and we appreciate your ability to provide this service to your clients. Our team’s experience in connection design will help ensure that the connections between steel members are strong, safe, and efficient, and that the final product meets or exceeds all safety standards and building codes.

We look forward to working with you and your team to provide our clients with the best possible structural design and drafting solutions. We believe that our combined expertise will result in successful projects that exceed our clients’ expectations. Please don’t hesitate

ProSteel 3D is also easy to use. Its developers have ensured that they make your work faster and easier by coming up with an interface where you can see toolbar buttons, pop-up menus or trays. Also, while hovering your mouse over the various choices in the menu you have open, you can see the changes to be made if you select that option.

Further, you can set your own steel standards with its open system. The details that you add will be added to a database that anybody can modify or edit. More than that, a user can use dBase or Excel to add new custom sizes and shapes.

The added flexibility translates to more productivity and efficiency. Further, it enables you to complete usual construction applications like structural steel, shelving, plant, steel building equipment and marine applications almost without difficulty!

ProSteel 3D, while using all the typical AutoCAD functionality, also adds its own set of functionalities, like:

There are too many functionalities to list down!

Further, ProSteel 3D has the capability to be used with other third party applications including air conditioning, petrochemical engineering, architecture, process engineering, and plant construction, among others. ProSteel 3D’s open architecture enables the user to use it in conjunction with other software!

Lastly, ProSteel 3D has various interfaces for different user needs. There are interfaces that are unique to steel fabrication and construction. This interface lists parts needed, components needed for building and some statistics, among other things.

Anybody who is an expert in AutoCAD will surely find ProSteel 3D very easy to use and learn. This is because ProSteel 3D uses AutoCAD commands in modifying different objects. In other words, there is not much of a learning curve and the company saves on the time it needs to train new users and the associated costs. It also gives you a more efficient and productive team in no time!

Are you looking for shop drawings or installation diagrams for workshop fabrication? Opt for a leading BIM service provider and get automated shop drawings from the HVAC models. However, before hiring a company, check out whether the diagrams are created as per the project standards and facilitating the suppliers, contractors, manufacturers and fabricators at the time of construction. If required, look at the various MEP shop drawing samples like the penetration sketches, insert layout sketches, sleeve drawings and spool drawings. Moreover, check whether the diagrams produced by the company can be downloaded directly in the GPS instrument on site for the creation of accurate layout.

Let’s explore the various Steel Structural shop drawings:

Installation Drawings – Installation sketches are often required for mechanical services of HVAC, plumbing, fire protection, piping and medical gas system. They help the contractions to execute, plan and install mechanical systems effectively, saving a lot of cash and time. Mechanical BIM services provide layouts in reference to architectural and structural specifications of clients and help them locate mechanical members easily.

Our Steel Detailing and Connection Design Services:

- Shop Drawings

- Steel Detailing and Modeling services

- Steel Fabrication Detailing and Drawings

- Miscellaneous Steel Detailing

- Conveyors Detailing and Design

- Industrial Steel Structures Detailing

- Conveyors & Hoppers Detailing

- 3D Steel Modelling

- 3D BIM Erection Drawings

- 3D Modelling

- Framing Plan Detailing

- Fabrication Drawings

- Erection Plan Detailing

- ABM (Advance bill of Material)

- Anchor Bolt Setting Plans

- Embed Plans

- Field Used Drawings/Erection Drawings

- Part Drawings

- TRUSS Detailing

- Coordination Drawings and designs

- Connection Sketches

- General Structural Steel Detailing

- Structural Steel Detailing

- Miscellaneous Metals Detailing

- Shop/Fabrication Drawings

- Steel detailing for process industry piping

- BOMs and Material take-offs

- Anchor setting plans

- Shop bolt summary

- Steel detailing for I-Beam & H-Beams sections

- Column-Beam joints steel detailing

- Post-tension detailing

- Pipe supporting structure

- Monorail supporting structure

- Misc. steel detailing

- Shop / Fabrication drawing

- Bolted connection details

- Structural 3d modeling

- Industrial structures

- Commercial buildings

- BIM structural models

- Industrial pipe rack assembly

- Industrial structural steel

Block-Out Drawings – Block-out diagrams also form a significant part of MEP shop drawings as they provide illustrations before pouring concrete on site. These sketches are often aligned with architectural grids. Expert Mechanical BIM service provider keeps necessary block-out clearance in accordance with the construction codes and contract documents and locate the openings accurately by the dimension of the real grid lines.

Sleeve, Insert & Hanger Diagrams – Sleeve, Insert and Hanger diagrams are important before concrete pouring and they are also aligned with architectural grids. These BIM based illustrations help to coordinate reviews and check interference with structural elements of the construction. The accurate positions of the sleeve and hanger assist the structural and civil construction team before plumbing installation.

Spool Drawings – Spool diagrams for pipes help the plumbers to understand the way of proceeding their work. These illustrations facilitate in making accurate pre-fabrication both on-site and off-site. So why are you waiting for? Get segmented spool diagrams generated as per your pre-fabricated standards and preference.

Equipment Detailing & Pad Layout – Diagrams showing the Sections and Isometric of mechanical equipment detail are required for installation of HVAC equipment from approved submittals in specific location. Get these illustrations created by an expert BIM service provider and coordinate effectively for seamless construction workflow.

Search for one of the best mechanical BIM service providers and prepare your coordination drawings with colour codes for easy removal of clashes. You could have the requirement for single line diagram or double line diagram with specific dimension and elevation. Furthermore, you may need to create sheet metal illustration for duct fabricator as per SMACNA codes. Whatever may be your criteria or standards regarding insulation thickness and essential linings for your HVAC duct system, let the mechanical shop drawing service provider know about it and ensure seamless coordination between sprinklers and mechanical piping. Before you ask for producing mechanical shop drawings, consider the drop ceiling level as well as the beam height. If necessary, also revise the sketches in accordance to the site survey notes.

4 thoughts on “Steel Detailing and Connection Design Services By Global Detailing Consultant”