Quality Shop Drawing and Steel Structural Shop Drawings – Shop Drawing Service Company – Steel Detailing Structural Steel Shop Drawing Services

The process is carried out in special manufacturing units equipped with requisite tools and machinery. The processing units are called fab shops in USA and elsewhere.

The process usually begins with:

Once the components are made they may be assembled to form one productive unit used in the building. The assembling process may involve welding, binding with adhesives or riveting. Next steps would be priming, powder coating, painting and sand blasting.

Popular use of fabrication technology is to make building components which are usually single components built at a fab shop and installed at construction site.

The use light weight structural steel, prefabrication technique employed at fab shops and subsequent installation at place of work nearby all accord monetary gains or benefits making the business profitable.

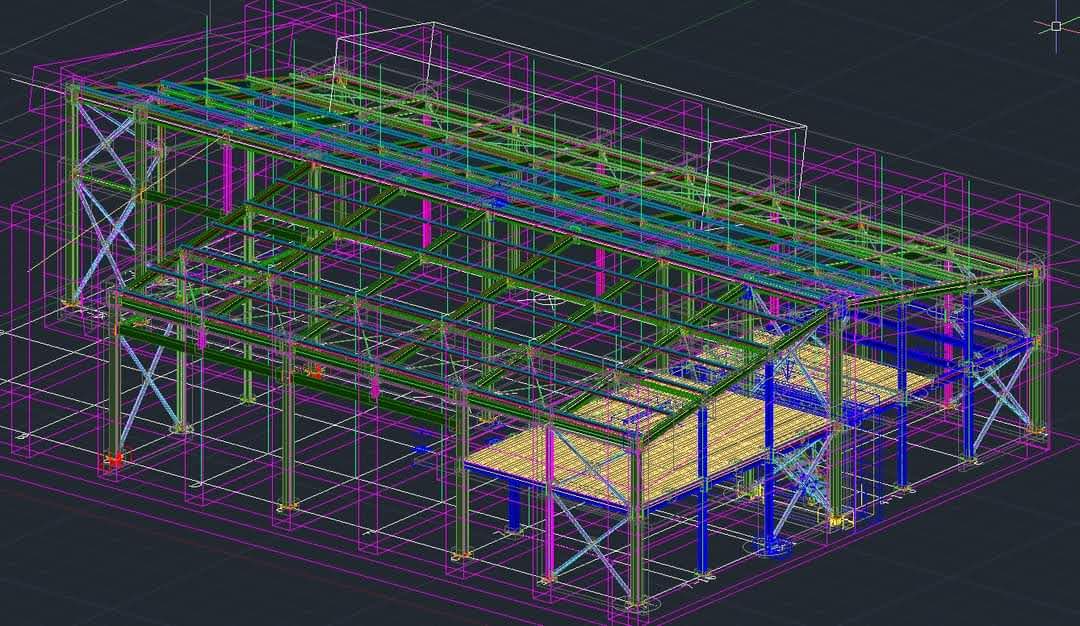

Not only components but structural steel work may also be used to make a skeletal frame of the building. This frame usually consists of columns and beams made from hot rolled steel which is bolted or riveted or welded together.

The initial step involves component drawings which usually describes the parts that comprise the unit. In the drawings specifications or component dimensions and physical and chemical properties may be highlighted. The mention of properties highlights the quality which is very important aspect of this business.

When more than one component is involved, it is called assembly and the assembly drawing refers to the components. The drawings are made regarding all aspects of building construction. The drawing is made using CAD software or other open source advance software.

The fabrication drawing are comprehensive and not just simple diagrams or lines. They provide detailed descriptions and specifications and a list that identifies all materials used. The drawing notes should clarify the heat treatments and stress relieving requirements as well.

Fab shops thus are comprehensive units in modern times with amalgamation of many technologies including computerization. In order to fabricate building components quality steel fabricators follow a strict methodology. The business has over the number of years become very competitive but rewarding.

Shop drawings are created for the purpose of illustrating construction or design projects. The materials that are to be used, the object dimensions, installation processes and information relevant to the successful completion of the project are often included. Shop drawings are typically a very important part of the construction or building process. This is especially true in today’s economy when the high costs associated with redesigning or reworking a project, can easily make or break it.

Shop drawings may be created by a sub-contractor, contractor, manufacturer, vendor, or even be outsourced. Having your shop drawings outsourced is sometimes the most practical approach for smaller businesses there is no longer a requirement to employ a full time draftsman and the drafting firm should have a higher knowledge level about design, standards, and building codes.

Before construction begins, the projects new shop drawings will need to be submitted for approval by the architect, general contractor, and / or client. These submitted drawings provide a rendering of the proposed project that is to be followed by those actually installing the job. Having clear and concise drawings, of whatever is being constructed, can be a great deal of help. Because it is a visual representation of what is being created, it is easier for those hired to construct it to accurately reproduce it.

Shop drawings play a pivotal role of the design process. In a way, they help to drive it. Only after a company agrees to the work presented in visual form, i.e., the shop drawings, are they ready to proceed with the project. Those hired to construct whatever is being built will refer to the drawings while they do so.

Our Shop Drawing Services & Steel Structural Shop Drawing Services

- Steel Shop drawings

- Stair Shop drawing

- Handrail Shop Drawing

- Sheet Metal Shop drawings

- Miscellaneous Drawings

- Millwork drawings

- Steel Fabrication Drawing

- Erection & GA diagrams

- Cabinets Shop Drawing

- Cabinets Shop Drawing

- CAD Shop Drawings

- Construction Shop Drawings

- Erection drawings & GA diagrams

- Fabrication Drawings

- Handrail Shop Drawing

- Millwork drawings

- Miscellaneous Steel Detailing

- Advanced bill of materials for steel shop drawings

- Precast Shop Drawings

- Rebar Shop Drawings

- Single Part Drawings

- Stair Shop drawing

- Working drawings for structures

- Connections Steel Detailing

Shop drawings are in short, a detailed visual representation of the pre-fabricated works of a structure. They are utilized by contractors, architects, designers and the like. Drawings such as these are useful because they can help decrease the likelihood of design issues that might develop and cause delays in a project. Shop drawings make it possible for those involved in the manufacturing or construction of the item in question, to avoid possible design errors and subsequent delays.

Companies that are not able to employ staff to create shop drawings, may want to outsource these duties to a drafting firm that is both experienced and exceptional in this area. The top companies can make this process a seamless one so that the drawings seem to be coming from the company itself. They are able to create drawings that fit the exact specifications and standards of a particular company. This is of course, only one option, albeit a good one. The alternative is to hire a staff member to perform this type of work. The beauty of outsourcing is that it is only necessary to hire someone when and if needed. Having someone on staff means that they have to be paid whether there is lot of work to be done or hardly any. A better option, in many cases, is to outsource these duties, especially in these uncertain economic times when there may be periods where the work is readily available work and times where there is hardly any.

4 thoughts on “Process of Generate the Quality Shop Drawing and Steel Structural Shop Drawings”

Comments are closed.