The Advantages of Accurate and Detailed Structural Steel Drawings

Structural steel detailing plays a crucial role in the construction industry, especially in projects that involve steel structures. It involves creating detailed drawings and specifications that provide accurate information for the fabrication, erection, and construction of the steel components. Here are some reasons why structural steel detailing is important in construction:

Steelwork detailing refers to the process of creating detailed drawings and models that specify the dimensions, connections, and other specifications for the fabrication and erection of steel structures. It is an essential part of the construction industry, as it ensures accurate and precise fabrication and assembly of steel components. Steelwork detailing is important for several reasons.

Firstly, it helps in visualizing and communicating the design intent to all stakeholders involved in the project, including architects, engineers, fabricators, and erectors. This ensures clarity and minimizes errors during the construction process.

Secondly, detailed drawings and models produced during steelwork detailing provide crucial information for fabrication, including material quantities, dimensions, and connection details. This information aids in the efficient production of steel components, reducing waste and cost. Additionally, accurate steelwork detailing ensures proper coordination and integration with other building systems, such as mechanical, electrical, and plumbing. This helps prevent clashes and conflicts during construction, saving time and resources. In summary, steelwork detailing plays a vital role in ensuring the successful and efficient construction of steel structures. It enhances communication, minimizes errors, optimizes fabrication, and promotes coordination among various project stakeholders.

Structural steel detailing plays a crucial role in the construction industry. It involves creating detailed drawings for fabricators and contractors, along with producing plans, estimates, and other essential reports. In this process, two types of drawings are used: shop drawings and erection drawings. These meticulous documents ensure seamless coordination between teams and facilitate efficient execution of projects.

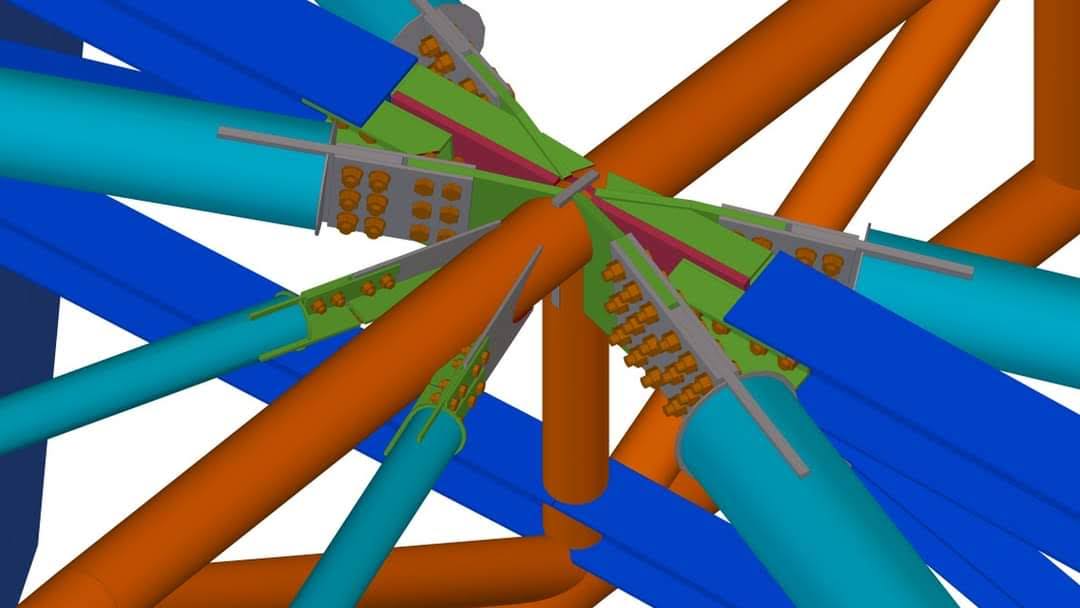

The erection drawings play a crucial role in construction projects. They provide precise information on the positioning of steel components within the structure and include detailed plans with accurate dimensions. These drawings not only outline the exact placement of each component but also specify installation requirements and any necessary fieldwork such as welding spots, wedge anchors, and bolts. By following these drawings, construction teams can ensure efficient and accurate assembly of the structure.

Shop drawings, unlike other types of drawings, are incredibly detailed and precise. Every steel element, from joists and beams to columns and braces, is meticulously described in these drawings. They provide explicit instructions on how steel fabricators should construct each component. These drawings include information on component dimensions, sizes, bolting techniques, welding processes, material specifications, and any other necessary details for the fabrication of each individual part. Rest assured that shop drawings leave no room for confusion or error in the construction process.

When it comes to constructing buildings, bridges, airports, and industrial plants, there is a consistent demand for an array of steel components. From sturdy columns and beams to reliable trusses, staircases, handrails, bracing, steel joists, and metal decking – the list goes on. These vital steel elements play a pivotal role in ensuring the strength and durability of structures large and small.

Without proper structural steel detailing, design, and engineering, these structures can be highly inefficient and prone to disastrous accidents. That’s why it’s crucial to ensure that sufficient attention is given to these aspects. Structural steel is renowned for its exceptional reliability, durability, and ability to withstand adverse weather conditions. This makes it an ideal choice for construction projects where safety and longevity are paramount considerations.

The collaboration between the structural engineer and fabricator plays a crucial role in ensuring the design, strength, and integrity of steel constructions. To streamline the fabrication and erection process, structural steel detailing becomes indispensable. It facilitates the creation of comprehensive structural drawings, design plans, and various construction documents necessary for a successful project execution.

The architect plays a crucial role in ensuring that all key measurements and construction codes are followed precisely. Meanwhile, steel detailing serves as a vital communication link within the project. By establishing strong collaboration between these professionals, potential mishaps during or after the construction process can be effectively avoided.

Steel detailing plays a critical role in ensuring effective communication among key project stakeholders, including steel fabricators, engineers, architects, and contractors. It acts as a vital link that connects these essential specialists, enabling smooth collaboration and coordination throughout the construction process.

- Accuracy and Precision: Structural steel detailing ensures that the steel components are accurately measured, sized, and positioned. Detailed drawings provide precise information on dimensions, connections, and quantities, which helps in minimizing errors and rework during fabrication and construction.

- Interoperability and Coordination: Steel detailing facilitates coordination among various disciplines involved in the construction process, including architects, engineers, fabricators, and contractors. Detailed drawings allow for effective communication and collaboration, ensuring that all parties are on the same page and working towards a common goal.

- Efficient Fabrication: Detailed drawings provide fabricators with all the necessary information to fabricate the steel components accurately and efficiently. This includes information on material specifications, welding details, bolt sizes, and connection requirements. Proper detailing helps reduce material waste, optimize fabrication processes, and improve overall productivity.

- Easier Assembly and Erection: Detailed drawings guide the erection process, providing clear instructions on how the steel components should be assembled and erected on-site. This minimizes errors and delays during construction, leading to a smoother and more efficient erection process.

- Safety Considerations: Structural steel detailing includes important safety considerations, such as ensuring proper load distribution, bracing requirements, and connection details. A well-detailed steel structure enhances safety by ensuring that the steel components can withstand the intended loads and forces without compromising structural integrity.

- Cost and Time Savings: Accurate and detailed steel drawings help reduce costly mistakes and rework during fabrication and construction. By minimizing errors, delays, and material wastage, structural steel detailing can result in significant cost and time savings for construction projects.

- Compliance with Codes and Standards: Steel detailing ensures compliance with relevant building codes and industry standards. Detailed drawings include information on structural requirements, material specifications, and connection details, ensuring that the steel components meet the necessary safety and performance standards.

In summary, structural steel detailing is essential for the successful execution of construction projects involving steel structures. It facilitates accuracy, coordination, efficiency, and safety throughout the fabrication and construction process. By investing in high-quality steel detailing, construction professionals can ensure the successful completion of steel projects while minimizing errors, reducing costs, and improving overall project outcomes.

At Global Detailing Consultant Inc, we are proud to have established partnerships with leading corporations worldwide. Our expertise lies in providing top-notch structural design, drafting, and detailing services catering to various industries such as fabrication, precast detailing, steel detailing, and general arrangement (GA) drawings. Since our inception in 2007, our mission has been to offer specialized CAD services with the convenience of outsourcing structural services to our esteemed global clientele. From residential developments to commercial ventures and industrial projects including power plants, oil and gas platforms, petroleum refineries, material handling plants – we can handle it all. When you choose us as your partner for structural drafts, rest assured that we will deliver exceptional results that meet your requirements and exceed expectations. Trust Global Detailing Consultant Inc for unparalleled expertise in the field of structural consulting services.

6 thoughts on “The Essential Role of Structural Steel Detailing in Construction Projects”