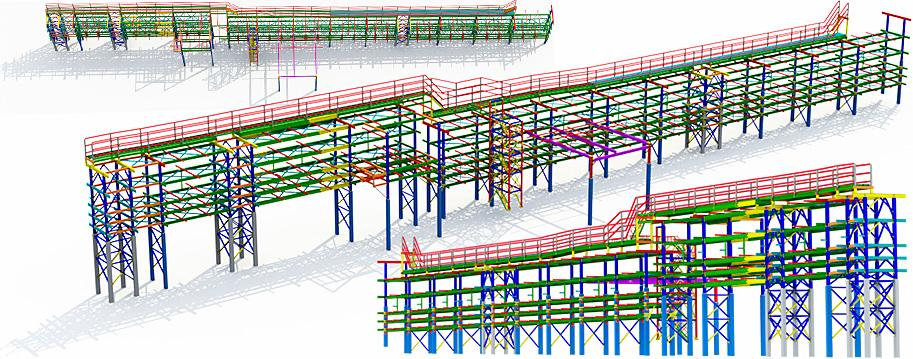

Pipe Rack Detailing, Designing Services, Analysis and Engineering Service – Design of Structural Steel Pipe Racks – Pipe Rack Steel Detailing Service Company – Structural Piperack Detailing Design Service

Pipe racks are utilized in the development of the petrochemical, synthetic, and electric force crops ventures. They should assist with pipes, electrical force links, and instrument link plates. At times, pipe racks help mechanical apparatuses, vessels, and valve acquire stages. On a very basic level, they can be a connection concerning machines and capacity or utility spots.

Global Detailing Consultant pipe rack detailing, designing services, analysis and engineering service, drawing and tank service. Our team of experienced professionals provides comprehensive pipe rack detailing services that include design, analysis, and engineering. We use the latest software and technology to create detailed drawings that meet all applicable building codes and safety standards. Our team has extensive experience in designing and detailing pipe racks for a variety of industries, including oil and gas, petrochemical, and power generation.

Our design and analysis services include evaluating the structural integrity of existing pipe racks, as well as designing new pipe racks that meet the unique requirements of each project. We also provide comprehensive engineering services that include stress analysis, load calculations, and material selection to ensure that each pipe rack is designed to meet the specific needs of the project.

In addition to pipe rack detailing, we also offer a range of drawing and tank services. Our team of experienced drafters can create detailed drawings for a variety of construction projects, including tanks, vessels, and other structures. We also provide tank design and analysis services, including evaluating the structural integrity of existing tanks and designing new

Pipe Rack Detailing

The most pivotal underlying segments of your line rack superstructure are:

- cross over pillars (upholds for channeling, etc.)

- segments

- longitudinal swaggers

- vertical propping

- Interconnecting/Main piperack (elevated)

- Unit piperack (elevated)

- Pipe track or sleeper way (at grade)

Some of Our expertise in Structure for Routing Pipes in the Plant:

- Pipe Rack Design

- Piping Stresses

- thermal expansion

- Piping Layout & Design

- Pipeline Design

- Pipe Rack Design Service

- Pipe Rack Cross section

- Piping Stress Analysis

- Piping isometrics

- Isometrics Drawing & Bill of Materials

- Piping Material Takeoffs

- Piping Instrumentation

- Pipe Rack Design & Piping Supports (Structural Detailing)

- 2D Piping Layouts

- 3D Piping Layouts

- Plot Plan Development

- Piping Design Criteria Development

- Pipe Sizing & Calculation

- Conceptual Pipe Routing

- Paper or Blue Print to CAD

- Heat Exchangers

- Pressure Vessel Design

- Pipeline

- Tank & Skid Fabrication

Plant Design Engineering Services

- Plot Plan, Equipment Layout and Skid Design

- Specifications based 3D Piping Modeling, Design, Orthographic Plan, Section, and Detail Preparation

- Pipe Stress & Flexibility Analysis

- Standard and Custom Pipe Support Design

- Piping System Walkdowns

- GA Drawings & Isometric Extraction

- Material Take Off for Piping, Valves and Insulation

- Piping System Revamp Engineering

- Piping System Integrity Audit

- PFD and P&ID redline markup update

- Process engineering support of all project lifecycle phases

- Process control narrative development

- Preparation of Process Documents (Equipment & Line List)

- Process Hazard Analysis (PHA)

- Hazard and Operability Study (HAZOP)

- Management of Change (MOC)

Mechanical Design & Analysis for Pressure Vessels

- Thermal and Mechanical design for Shell and Tube Heat Exchangers

- Design and detailing of Boilers, Storage tanks & Silos

- Preparation of GA and fabrication drawings

- Structural Design & Analysis, Fabrication Drawings

- Equipment Support, Walkway, Ladder and Platform Design

- Foundation Drawings

- Connection Design

- Lifting arrangement design

- Cast-in-place concrete structures

- Monorail / Hoist systems

- Civil & Structural Material Take Off

- 3D Modeling & Steel Detailing

- Junction Box design

- PLC Programming

- Heat tracing Layout and Electrical Circuit details preparation.

Creation of: Instrument Hook-up Diagrams, Single Line Diagrams (SLD), Instruments List & Logic Diagrams, Cable Schedule and Wiring connection list, Electrical circuit drawing, Installation drawing, Electrical GA Drawings, Wiring Diagrams and Wiring Lists, Hazardous Area Classification Drawings, Control System Architecture, Instrument Specifications and Data Sheets, Insulation procedure, Bill of Materials, Branch Circuit layouts & Panel arrangement, 3D Modeling of Cable Trays and Instrument Panels

When thinking of Pipe racks, the Structural Engineer will remember the upkeep, allowing straightforward openness underneath the Pipe rack. Thus, second opposing casings (MRF) are utilized or the supporting is confined uniquely to various straights.

You will discover commonly two kinds of line racks:

- Strutted

- Unstrutted

The principal style swaggered, has longitudinal swaggers including the cross over edges. This expansion gives solidness during the longitudinal course. Additionally, corner to corner propping can be added in order to act along with the longitudinal swaggers to oppose the level masses. This plan is normal.

The unstrutted pipe rack doesn’t hold the longitudinal swaggers, henceforth the segments function as cantilevers to oppose parallel burdens longitudinal towards the line rack.

Usually, if applying swaggered pipe racks, the sections will Ordinarily be created with stuck or set base, as indicated by the parallel floating requests.

For unstrutted pipe racks, sections will be seen as stuck inside the cross over course and stuck during the longitudinal way. The principal pivot of sections should be opposite to the longitudinal way of your line rack.

PIPE Racks:

- Structural steel pipe racks ordinarily uphold pipes, power links and instrument link plate in petrochemical, substance, water treatment and force plants.

- Occasionally, pipe racks may likewise uphold mechanical gear, vessels and valve access stages.

- Main pipe racks by and large exchange material among hardware and capacity or utility regions.

13 thoughts on “Pipe Rack Detailing | Designing Services Analysis and Engineering Service”