The Art and Science of Designing and Detailing Load Bearing Structure Elements – Key Concepts and Principles in Load Bearing Structure Design

With over 29 years of experience, Global Detailing Consultant has been a trusted manufacturer of steel load-bearing structures. Our commitment to high reliability ensures that the buildings we help construct are built to last. Our reputation for delivering quality services is well-established both in Estonia and internationally.

We understand that each region has its own unique standards and specifications. That’s why we prioritize tailoring our products to meet the specific legislative requirements of your country. By choosing us, you can be confident that you will receive a product that complies with all necessary regulations.

Our team takes the time to carefully assess your needs and design load-bearing structures that are precisely suited for your project. With our expertise and attention to detail, you can trust us to deliver results that exceed your expectations.

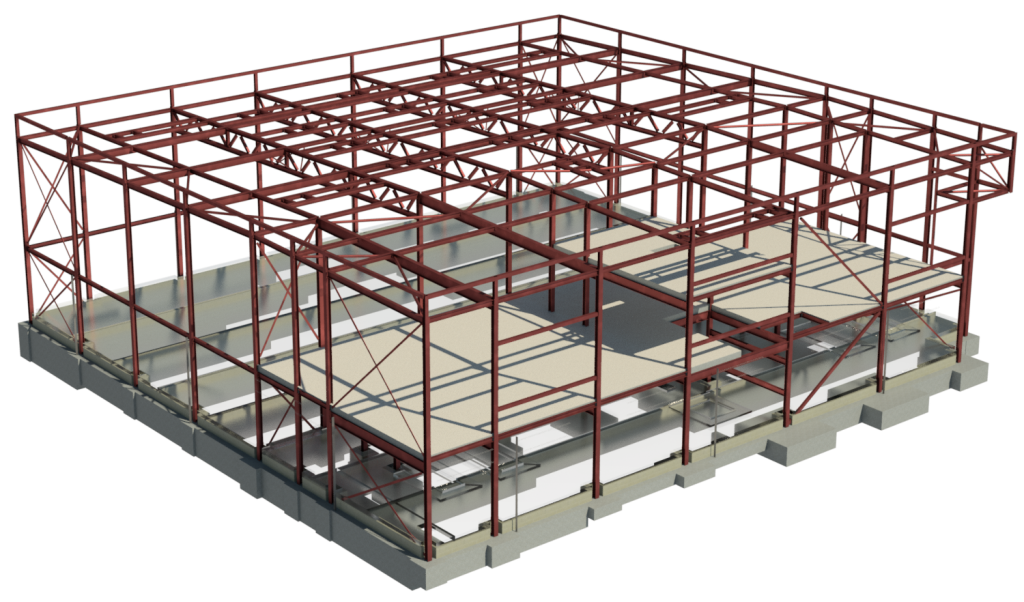

LOAD BEARING STRUCTURE CONSTRUCTION OVERVIEW

Load bearing structures are meticulously designed to withstand the weight of various loads, ensuring stability and safety for the entire building. Serving as the backbone of any structure, these frameworks bear both constant and climatic loads that exert pressure on the foundation. In terms of construction, fasteners play a crucial role in supporting the roof construction and longitudinal walls. Meanwhile, gable columns provide essential support to gable walls. This strategic arrangement ensures that every element of the structure is well-supported and capable of withstanding external forces.

In order to establish strong structural connections, cross skeletal connections often involve the use of robust wall columns with either solid frames or lattice beams. As needed, additional support can be provided through the inclusion of runway beams, intermediate floors, and other components to reinforce the standard load bearing frame.

Supporting structures set themselves apart from frame structures due to their unique responsibility of transmitting and bearing the subsoil load. In load-bearing structures, walls play a vital role in supporting the load, while frame structures rely on columns and beams for this purpose. These distinctive elements ensure stability and durability in their respective construction designs.

The system offers a complete superstructure solution for buildings, equipped with load-bearing properties. Some of the key structural elements responsible for bearing the main loads include:

- Beam

- Columns

- Walls

- Braces

- Trusses

DESIGN OF LOAD BEARING STRUCTURE

Attention: It is crucial to emphasize that the thorough design of the load-bearing structure should be meticulously handled by our proficient team prior to commencing any construction activities on-site. To enhance the workflow efficiency, it is recommended for the project team to furnish essential architectural details:

- When it comes to the placement of walls and superstructures, careful consideration is essential. The positioning of these elements can greatly impact the overall stability and functionality of a structure. By ensuring precise placement, you not only enhance the structural integrity but also optimize the utilization of space. A well-planned arrangement leads to efficient flow and distribution within a building, resulting in an aesthetically pleasing and practical design.

- The layout of wall openings.

- Enhance the look of your space with our impeccable flooring solutions and expert finishing services. Whether it’s a residential or commercial project, we have you covered. Our team of skilled professionals will ensure that every inch of your floor is perfected to perfection, leaving no room for compromise. Transform any space into a stunning masterpiece with our top-notch flooring and finishing services.

- Our team is highly skilled in handling the assembly and installation of roofs, along with all of its components such as cornices, parapets, hatches, and more. With our expertise and attention to detail, you can trust that the job will be completed seamlessly and to your utmost satisfaction. Let us take care of every aspect of your roof installation to ensure a durable and aesthetically pleasing result.

- Achieving a strong and secure connection between parts is essential, and that’s where support elements come into play. By strategically incorporating these elements, you can ensure the stability and durability of your products. Whether it’s in manufacturing, construction, or any other industry, connecting parts with support elements guarantees a reliable end result.

LOAD BEARING STRUCTURE BENEFITS

At Global Detailing Consultant, we take pride in our expertise in designing and detailing load bearing structures that not only meet but exceed fire resistance requirements. Our state-of-the-art production facilities enable us to offer customers load bearing structures with various coating options such as metal, duplex coating, or hot-dip galvanizing. Rest assured that our load bearing structures are certified and fully compliant with EN 1090-1 standards, making them eligible for the prestigious CE mark labeling. With us, you can trust that you are getting top-quality and reliable load bearing structures for your projects.

When compared to traditional building methods, the system under consideration boasts multiple notable advantages. These advantages serve as strong reasons for its implementation and adoption.

- Light weight

- Quick styling

- High strength

- Functionality in a confined space.

The versatility of load bearing structures makes them the perfect choice for penthouses or multi-level buildings that need to minimize the load. Not only does this provide structural stability, but it also helps to reduce costs related to cranes and product delivery when compared to pre-panel solutions.

Designing and detailing load-bearing structure elements requires careful consideration of various factors. Beams, columns, and slabs are vital components that bear the weight of the structure. To ensure their effectiveness, it is important to take into account several key considerations. Here are some essential factors to keep in mind:

- Load Analysis: The first step in designing load-bearing structure elements is to analyze the different types of loads that the structure will be subjected to. This includes dead loads (weight of the structure itself), live loads (occupant or equipment loads), wind loads, snow loads, and seismic loads. Properly analyzing and understanding these loads will determine the size and strength requirements of the structural elements.

- Structural Material Selection: Choosing the appropriate material for load-bearing elements is essential. Common materials include reinforced concrete, structural steel, or a combination of both. Factors such as structural requirements, cost, availability, and construction method should be considered when selecting the material.

- Structural Design Codes and Standards: Designing load-bearing elements must comply with local building codes and standards. These codes provide guidelines regarding the minimum requirements for material strength, design loads, safety factors, and other design considerations. Adhering to these codes ensures that the structure will be safe and structurally sound.

- Structural Analysis and Design Software: Advanced computer-aided design (CAD) software and structural analysis tools are used to model the load-bearing elements and perform structural analysis. These tools help engineers calculate the required sizes, reinforcement details, and connections for the elements based on the applied loads and material properties.

- Structural Detailing: Detailing is a critical step in the design process. It involves providing clear and accurate drawings and specifications for the construction of load-bearing elements. The detailing process includes dimensions, reinforcement details, connections, and any other information necessary for the successful construction of the elements.

- Constructability and Practicality: Designing load-bearing elements should also consider constructability and practicality. This means ensuring that the design can be easily implemented on-site within the given constraints, such as available construction methods, equipment, and labor.

- Quality Control and Inspections: Quality control measures should be implemented during the construction phase to ensure that the load-bearing elements are built according to the design specifications. Regular inspections and testing of materials and workmanship are essential to verify compliance with the design and ensure the structural integrity of the elements.