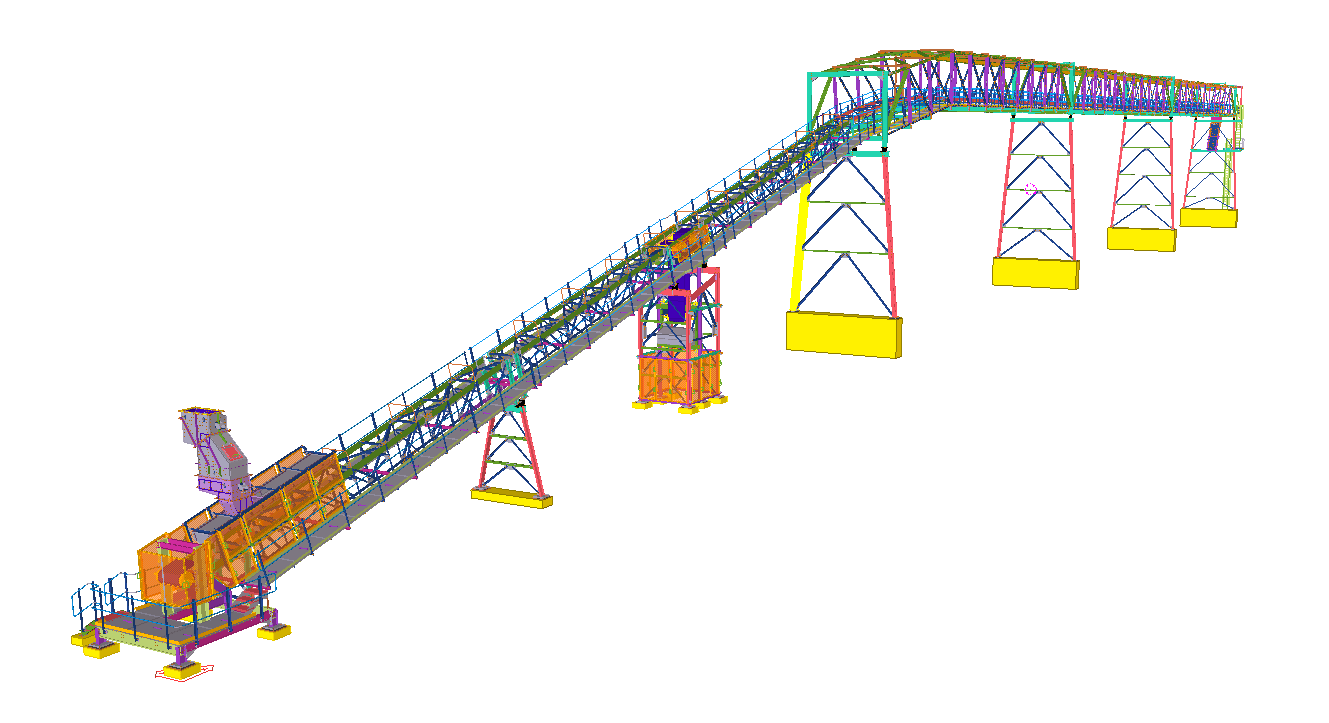

Material Handling Structures Design and Detailing by Global Detailing and Designing

At Global Detailing and Designing, we recognize the crucial role that efficient material handling structures play in enhancing the safety and productivity of any production system. Our commitment to excellence ensures that each structure we design and fabricate not only meets but surpasses the operational needs and safety standards required by our clients.

Our team of seasoned engineers and designers collaborates closely with every client to tailor solutions that are both innovative and practical, ensuring seamless integration into existing systems. By leveraging cutting-edge technology and industry best practices, we guarantee structures that not only optimize workflow but also reduce downtime and maintenance costs.

Our dedication to quality control means that each material handling structure undergoes rigorous testing before deployment, offering you peace of mind with every project. Choosing Global Detailing and Designing means investing in a partner who prioritizes your success through increased efficiency and safety. Let’s work together to elevate your production capabilities to new heights.

Expert Design and Comprehensive Solutions

Our expertise spans a wide range of material handling systems, designed to improve workflow and minimize the risks associated with the handling of heavy loads, dynamic materials, and hazardous chemicals. We provide comprehensive solutions that encompass not only the structural design but also the integration of hydraulic and electrical systems necessary for the operation of these handling assemblies. By choosing our services, you invest in a future-proof system that enhances efficiency and safety across your operations. Our dedicated team of engineers works closely with clients to tailor each solution to their specific needs, ensuring seamless integration with existing infrastructure and processes.

Our commitment to quality is demonstrated through rigorous testing and adherence to industry standards, guaranteeing reliability and longevity in every project we undertake. Partnering with us means gaining access to cutting-edge technology and innovative designs that keep you ahead of the competition while optimizing your material handling capabilities. With our support, you can transform challenges into opportunities for growth by reducing downtime, increasing productivity, and safeguarding your workforce. Let us help you achieve operational excellence with our unparalleled expertise in material handling solutions.

Global Detailing Consultant team has done bulk material handling system from pre-bid stage to execution stage. It includes PFD, Layout, System Plan & Sections, Design, Selection of equipments, detailing of plant material handling system. We have done projects in different handling materials-i.e.

- Coal Handling

- Coke Handling

- Flux handling i.e. Limestone, Dolomite, Bentonite etc.

- Iron Ore Benefication

- Coal Washery

- Cement Plant

- Sinter Plant

- Pellet Plant

- DRI Plant

- Rolling Mills(hot & cold)

- Steel Melting Shop

- Skew Rolling Mill

Solid Handling

- Design of conveyor system including power calculation, drive equipment selection calculation, curvature calculation, counter weight calculation, shaft design etc.

- Preparation & design of system elevation, plan, cross-sections.

- Preparation of conveyor GA & detailing of all components.

- Preparation of technical specification & technical evaluations of different offers.

- Design, GA & detailing of feeders, Belt weigh machine, Shuttle conveyors, Stacker, Tripper car, Wagon tippler, reclaimer etc.

- Design of pneumatic conveying system along with GA & detailing.

- FEA analysis of different components of conveyors i.e. drive frame, pulley frames etc. with SOLIDWORKS SIMULATION.

- Technical checking of conveyor design, GA & detailing etc.

- GA, Design & detailing of hoppers, vibrating hopper etc.

Equipment & Machinery.

- Design, GA & detailing of SG, DG, US cranes.

- Preparation of technical specification & technical evaluations of different offers.

- FEA analysis of different components of crane i.e. crab, LT, hoisting frame etc. with SOLIDWORKS SIMULATION.

- Design,GA & detailing of grab bucket.

- Motion analysis of grab bucket.

Applications of Our Material Handling Systems Include:

– Conveyor Sections: Efficiently designed to transport materials across various stages of the production process.

– Offloading Systems: Engineered to safely and quickly move products from transport vehicles into storage or production lines.

– Transfer Systems: Optimized for seamless transition of materials between different equipment and processes.

– Heavy Material Flipping or Rotating Stations: Customized solutions to handle heavy loads that require flipping or rotating during the manufacturing or assembly process.

– Storage or Painting Racks: Structurally sound racks designed for storing or holding materials during processes such as painting or assembly.

Tailored Designs for Enhanced Efficiency

To ensure that our designs align perfectly with your operational requirements, Global Detailing and Designing encourages clients to provide detailed specifications of their needs. For an accurate and competitive quotation, please provide us with comprehensive data including:

– Material Handling System Functional Requirements: Specify the operational capabilities and functions needed in the system.

– Location: Where will the system be installed or utilized?

– Overall and Critical Dimensional Requirements: Dimensions are critical for ensuring the fit and function of the designed structures.

– Layout Drawings: Visual diagrams or plans of the proposed system help in refining the design process.

– Access Constraints: Any limitations in terms of accessibility for installation or maintenance.

– Full Range of Materials Handled: Information on the weight and dimensions of materials to be handled, ensuring the system’s capacity to manage them effectively.

– Any Other Useful Information: Additional details that might impact the design and functionality of the handling system.

Choose Global Detailing and Designing

Opting for Global Detailing and Designing means selecting a partner dedicated to delivering material handling structures that boost efficiency, safety, and productivity. Our experienced engineers are equipped to provide innovative, durable, and effective solutions tailored to meet the specific demands of your operations. Let us help you achieve operational excellence with structures designed for success. Contact us today to move forward with your material handling system needs.