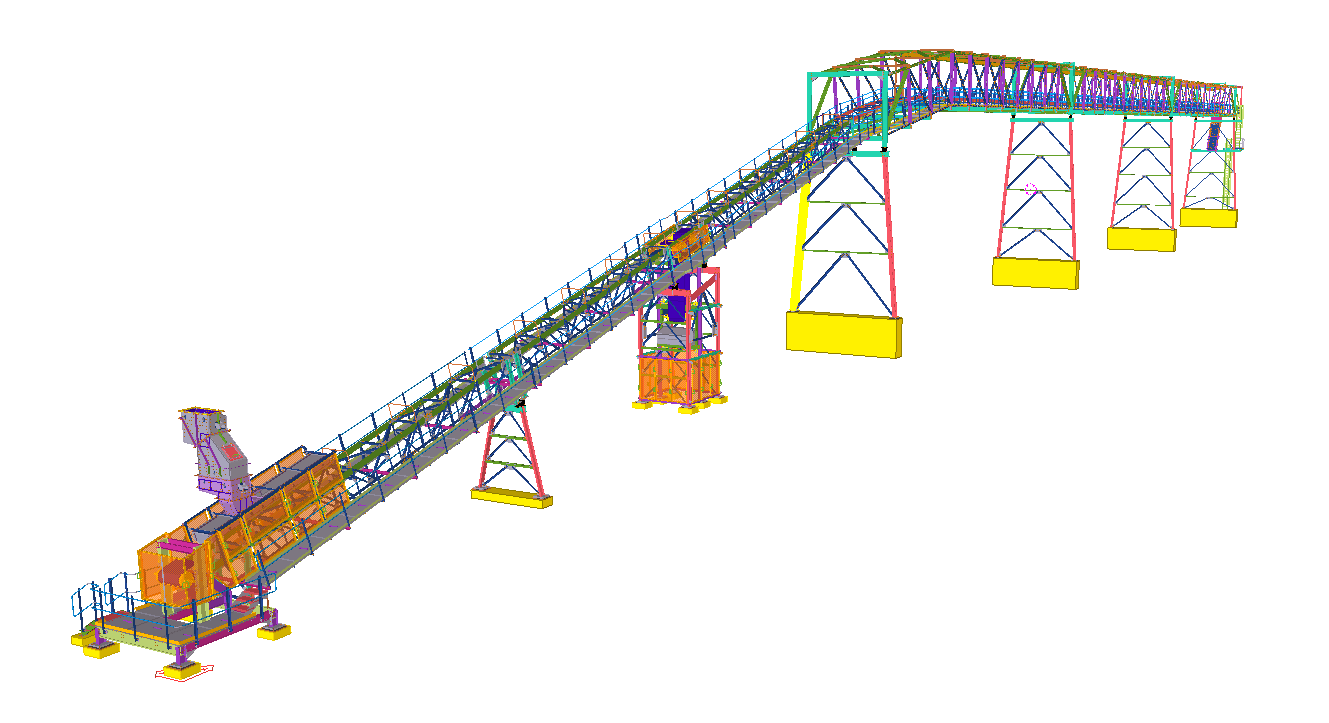

Conveyor Systems Design and Engineering Solutions by Global Detailing Consultant

At Global Detailing Consultant, we specialize in the design and engineering of conveyor systems tailored to meet the specific needs of manufacturing facilities. Our expertise covers a comprehensive range of conveyor types, each suited to different applications, ensuring materials and products are moved efficiently and safely across the production floor.

With years of experience and a dedicated team of professionals, we pride ourselves on delivering solutions that enhance productivity and streamline operations. Our systems are designed with precision to integrate seamlessly with existing workflows, minimizing downtime and maximizing efficiency. By choosing Global Detailing Consultant, you’re not just investing in equipment—you’re investing in a partner committed to driving your success.

Whether you require custom configurations or need advice on optimizing your current setup, our experts are ready to assist you every step of the way. Trust us to transform your manufacturing facility into a model of modern efficiency and reliability.

Diverse Range of Conveyor Systems

Belt Conveyors: Ideal for transporting a large volume of materials, these conveyors use a continuous belt over rollers and are perfect for handling heavy items.

Roller Conveyors: Best for moving materials in a straight line, these are equipped with rollers mounted on a frame, facilitating easy transport of goods.

Chain Conveyors: Designed for heavy or bulk materials, such as pallets or large containers, these conveyors utilize a robust chain mechanism.

Slat Conveyors: Using slats or plates attached to a chain, these are suited for transporting heavy-duty materials like large machines or automotive parts.

Screw Conveyors: Featuring a rotating screw mechanism, these are commonly used for bulk materials or powders, such as grains or cement.

Overhead Conveyors: Suspended from the ceiling, these systems are often utilized in assembly lines or painting processes.

Pneumatic Conveyors: Using a compressed air system to move powders, granules, or lightweight materials through pipes or tubes.

Vibrating Conveyors: Employing vibratory motions, these are ideal for transporting fragile or delicate items like glass bottles or electronic components.

Magnetic Conveyors: Utilizing magnets beneath the belt, these systems are effective in metalworking or recycling industries to move ferrous materials.

Bucket Conveyors: With buckets attached to a chain or belt, these are used for vertical or inclined transport of bulk materials like grains or fertilizers.

Custom Conveyor System Design Considerations

When designing custom conveyor systems, Global Detailing Consultant considers several critical factors to ensure the system is durable, efficient, and operator-friendly: First and foremost, we analyze the specific needs of your operation, taking into account the types of materials being transported, their weight, size, and handling requirements. This ensures that each conveyor is tailored to optimize performance for your unique processes.

We evaluate the layout and space constraints of your facility. By doing so, we can design a system that maximizes efficiency and flow while minimizing unnecessary complexity or disruptions in your production line. We also prioritize safety by incorporating advanced features such as emergency stop mechanisms and protective barriers to safeguard operators from potential hazards.

Our team stays up-to-date with industry regulations to ensure compliance with all safety standards. Energy efficiency is another critical consideration; thus, our designs integrate energy-saving technologies that reduce operational costs without compromising on performance. We select components known for their durability and low maintenance needs to extend the longevity of the system. Lastly, our user-centric approach means we focus on creating systems that are not only easy to operate but also straightforward to maintain.

Through intuitive controls and accessible design elements, we aim to enhance operator satisfaction while reducing downtime due to maintenance issues. By addressing these key factors comprehensively in every project we undertake at Global Detailing Consultant, you can trust us to deliver custom conveyor solutions that meet your current demands while anticipating future growth opportunities.

– Operator Safety: Adhering to safety regulations is paramount. We design systems that protect operators with the appropriate safety measures and ergonomic considerations.

– Material Characteristics & Durability: Understanding the specific materials to be handled allows us to design conveyors that are resistant to wear and tear, thereby extending their lifespan.

– Throughput Requirements: We tailor conveyor systems to meet high throughput demands, ensuring that they can handle the required capacity efficiently.

– Layout and Space Constraints: Our designs take into account the available space, optimizing the layout to maximize efficiency and integrate seamlessly with existing operations.

– Environmental Factors: Factors such as temperature, humidity, and exposure to chemicals are considered to ensure the conveyor system operates reliably under all conditions.

– Ease of Maintenance & Accessibility: We design for ease of maintenance, ensuring that conveyor systems are easily accessible for routine checks and repairs.

– Power Efficiency: Our systems are engineered to be energy-efficient, reducing operational costs and environmental impact.

Partner with Global Detailing Consultant

Choosing Global Detailing Consultant means partnering with a leader in conveyor systems design and engineering. Our expertise and commitment to quality ensure that your manufacturing facility benefits from a conveyor system that is not only efficient but also robust and safe. Contact us today to discuss how we can assist you in optimizing your production floor with our advanced conveyor solutions.

Connect with us on info@global-detailing.com